Silicone Duct Hose in Aerospace: Meeting High Standards

In the aerospace industry, every component must meet the highest standards of safety, reliability, and performance. Silicone duct hoses, flexible tubes essential for transporting air and gases within aircraft and spacecraft, are critical to this mission. These hoses endure extreme conditions while maintaining integrity, ensuring the safe operation of vital systems. This article explores how silicone duct hoses are designed, manufactured, and tested to meet the rigorous demands of aerospace applications.

High Standards in Aerospace

Aerospace components are governed by strict regulations from bodies like the Federal Aviation Administration (FAA) and the European Aviation Safety Agency (EASA). For silicone duct hoses, these standards include temperature resistance ranging from -60°C to over 200°C, pressure tolerance, flame retardancy, low smoke and toxicity emissions, and resistance to vibration and fatigue. Compliance is mandatory, as any failure could lead to catastrophic consequences. These requirements ensure that hoses perform reliably in the harsh environments of flight, from high-altitude pressure changes to engine-induced vibrations.

Why Silicone?

Silicone is the material of choice for duct hoses due to its exceptional properties. Its thermal stability allows it to remain flexible and durable across a wide temperature range, critical for aerospace applications. Silicone also resists ozone, UV light, and aging, making it ideal for prolonged exposure to demanding conditions. Furthermore, its lightweight nature enhances aircraft efficiency, a key consideration where every gram impacts fuel consumption and performance.

Design and Manufacturing Excellence

To meet aerospace standards, silicone duct hoses are meticulously designed and manufactured. Advanced silicone formulations are often reinforced with fabrics or wires to boost strength and pressure resistance. Precision molding and curing techniques ensure consistent quality, while custom shapes and sizes are crafted to fit the tight spaces within aircraft systems. The manufacturing process prioritizes durability and reliability, balancing high performance with the need for lightweight construction.

Rigorous Testing and Certification

Testing is a cornerstone of ensuring compliance with aerospace standards. Silicone duct hoses undergo a battery of rigorous evaluations, including burst pressure tests, temperature cycling, flame exposure, and vibration simulations. Standards like SAE AS150 specify tests such as pressure impulse testing, simulating real-world conditions with repeated cycles. FAA flammability tests ensure hoses do not propagate fire or emit harmful smoke and toxic gases. Only after passing these exhaustive assessments are hoses certified for aerospace use.

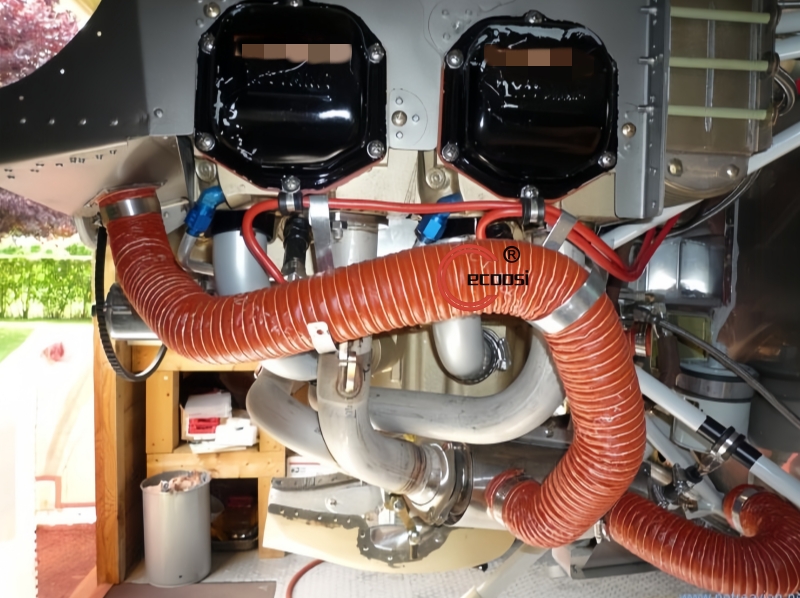

Applications in Aerospace

Silicone duct hoses are integral to various aerospace systems. In commercial aviation, they support environmental control systems for cabin pressurization and air conditioning, as well as bleed air systems that tap hot engine air for heating and de-icing. In space, the International Space Station relies on these hoses for air circulation, where absolute reliability is non-negotiable. Their ability to handle high temperatures and pressures while maintaining flexibility makes them indispensable.

Challenges and Innovations

The aerospace industry continually seeks to enhance silicone duct hoses. Challenges include reducing weight, increasing temperature resistance, and balancing performance with cost-effectiveness. Silicone’s superior properties come at a higher cost, prompting manufacturers to optimize designs and minimize material use without sacrificing quality. Innovations like new silicone composites and 3D printing are pushing the boundaries, improving durability and performance for future applications.

Conclusion

Silicone duct hoses are vital to aerospace, meeting stringent standards through advanced materials, precision manufacturing, and rigorous testing. They ensure the safe and efficient operation of critical systems in aircraft and spacecraft. As technology advances, these hoses will continue to evolve, supporting the industry’s pursuit of excellence in safety and performance.

Ecoosi specializes in industrial hose solutions. If you have questions or need additional information about our flexible hoses, please do not hesitate to click contact us or send an email to:info@eiduct.com or Whatsapp to:+86-187-1155-3123, or our other website:ductinghose.com, we will try our best to support you!

German

German French

French Spanish

Spanish Portuguese

Portuguese Russian

Russian Japan

Japan Italian

Italian

Send Email

Send Email Jim5040

Jim5040