How Silicone Duct Hoses Enhance Automotive Performance

Silicone duct hoses have become a cornerstone in high-performance automotive engineering, offering a suite of advantages that elevate vehicle efficiency, reliability, and power output. Used extensively in turbocharged engines, racing applications, and exhaust systems, these hoses outperform traditional rubber alternatives in demanding conditions. This article explores how silicone duct hoses enhance automotive performance through their unique properties.

Heat Resistance for Extreme Conditions

One of the primary benefits of silicone duct hoses is their exceptional heat resistance. While rubber hoses begin to degrade at temperatures above 250°F, silicone can withstand temperatures exceeding 350°F, depending on the formulation. This makes them indispensable in high-stress environments like turbocharged engines, where boost pressures and hot exhaust gases generate intense heat. For instance, in a turbocharged Subaru WRX, the hose linking the turbocharger to the intercooler can face temperatures over 300°F during spirited driving. Silicone hoses maintain their structural integrity under these conditions, preventing leaks or failures that could sap engine power and ensuring consistent performance.

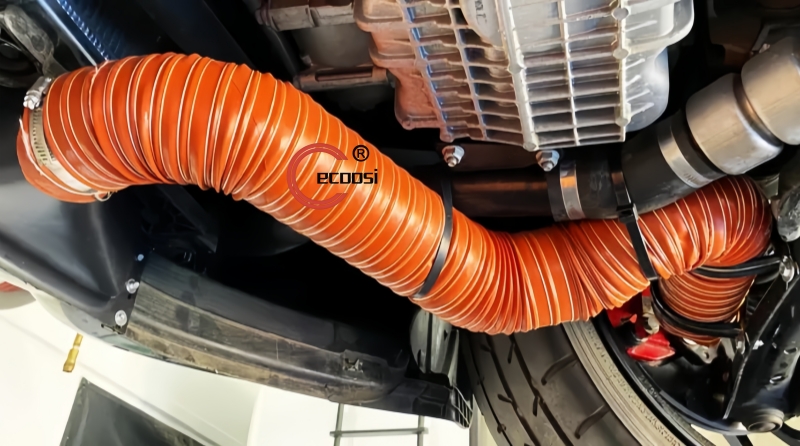

Flexibility for Complex Engine Designs

Modern engine bays are often tightly packed, requiring hoses to navigate sharp bends and confined spaces. Silicone duct hoses excel here due to their superior flexibility compared to rubber. This pliability allows for easier installation and routing without the risk of kinking or collapsing, which can restrict airflow and hinder performance. In a vehicle like the Honda Civic Type R, where space is at a premium, silicone hoses enable engineers and tuners to optimize component layouts. By maintaining unobstructed airflow paths, these hoses contribute to improved system efficiency and overall vehicle performance.

Durability for Long-Term Reliability

Durability is another area where silicone duct hoses shine. Unlike rubber, which can crack, harden, or deteriorate when exposed to heat, oil, and environmental contaminants over time, silicone resists these factors effectively. This resilience translates to a longer lifespan, reducing the frequency of replacements and associated downtime. In endurance racing, where reliability can make or break a race, teams frequently opt for silicone hoses to minimize the risk of mid-event failures. For performance enthusiasts, this durability means less time in the garage and more time pushing their vehicles to the limit.

Improved Airflow for Marginal Power Gains

While reliability and longevity are the primary draws, silicone duct hoses can also offer subtle performance boosts. Their smoother interior walls reduce turbulence compared to rubber hoses, promoting more efficient airflow. In high-flow applications, such as turbo or supercharged setups, this can translate to slight power increases—perhaps a few horsepower in a highly tuned engine. Though modest, these gains are significant in competitive scenarios where every fraction of performance counts.

Conclusion

Silicone duct hoses enhance automotive performance by delivering unmatched heat resistance, flexibility, and durability. They ensure reliability under extreme conditions, enable optimized engine designs, and reduce maintenance demands. For automotive enthusiasts and professionals aiming to maximize efficiency, reliability, and power, upgrading to silicone duct hoses is a smart investment that pays dividends on the road or track.

Ecoosi specializes in industrial hose solutions. If you have questions or need additional information about our flexible hoses, please do not hesitate to click contact us or send an email to:info@eiduct.com or Whatsapp to:+86-187-1155-3123, or our other website:ductinghose.com, we will try our best to support you!

German

German French

French Spanish

Spanish Portuguese

Portuguese Russian

Russian Japan

Japan Italian

Italian

Send Email

Send Email Jim5040

Jim5040