Comparing Silicone Duct Hose to PVC and Rubber Alternatives

Duct hoses are vital components across numerous industries, acting as conduits for air, gases, and occasionally liquids. They are employed in diverse applications, from automotive systems to industrial ventilation. The material of a duct hose significantly influences its performance, durability, and suitability for specific conditions. Among the most widely used materials are silicone, PVC (polyvinyl chloride), and rubber. Each offers unique properties that make it advantageous in certain scenarios while less effective in others. This article examines silicone duct hoses in comparison to their PVC and rubber counterparts, focusing on their properties, performance, and cost.

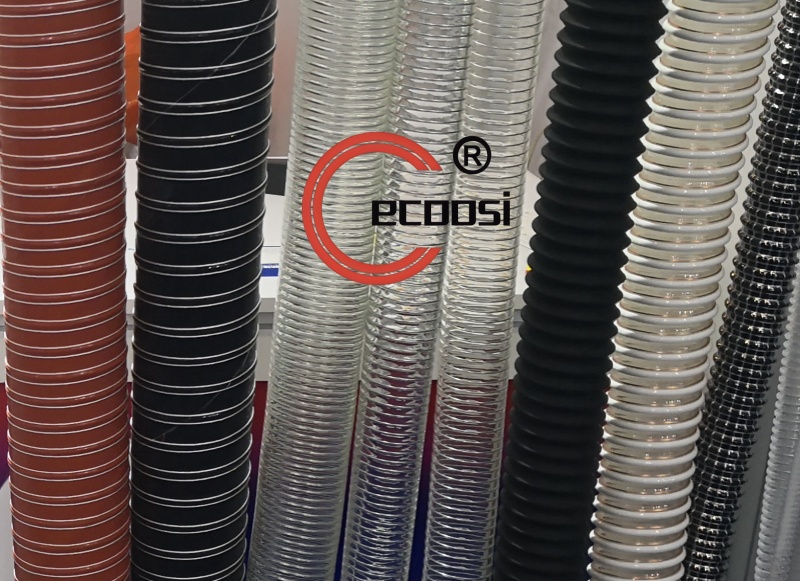

Properties of Silicone, PVC, and Rubber Hoses

Silicone hoses are celebrated for their remarkable temperature resistance, enduring extremes from -50°C to over 200°C. This makes them perfect for high-heat environments like automotive turbocharger systems or industrial exhaust setups. Their flexibility persists even in cold conditions, preventing brittleness or cracking. Silicone also boasts durability, resisting ozone, UV light, and weathering, which contributes to a longer lifespan in harsh settings. However, this superior performance comes with a higher price tag.

PVC Duct Hoses

PVC hoses stand out for their affordability and lightweight construction. They excel in chemical resistance, handling mild acids, alkalis, and other fluids, which suits them for laboratory or chemical transfer applications. Easy to manage and install, PVC hoses are practical for less demanding tasks. However, their temperature tolerance is limited, typically maxing out at 60°C, beyond which they may become brittle and crack. Prolonged exposure to sunlight or harsh weather can also degrade them over time.

Rubber Duct Hoses

Rubber hoses are prized for their strength and durability, especially where abrasion resistance is essential. They can manage moderate temperatures, up to around 120°C, and are common in industrial air and water transfer systems. While resistant to some chemicals, rubber is less versatile in this regard than PVC. These hoses are heavier and less flexible than silicone or PVC, complicating installation. Additionally, rubber can deteriorate under UV light, ozone, or specific chemicals, shortening its lifespan in certain conditions.

Performance Comparison in Various Applications

The ideal duct hose material hinges on the application's demands:

High-Temperature Environments: Silicone hoses shine here, maintaining flexibility and integrity in extreme heat. They are indispensable in automotive and industrial high-heat scenarios where PVC and rubber would falter or degrade.

Chemical Resistance: PVC hoses take the lead in chemical-heavy settings, resisting a broad range of substances. This makes them suitable for labs or chemical plants, whereas silicone and rubber have narrower chemical compatibility.

Abrasion and Durability: Rubber hoses are robust, thriving in abrasive industrial environments. They withstand physical wear better than silicone or PVC, ideal for heavy-duty use.

Flexibility and Weight: Silicone and PVC hoses offer greater flexibility and lighter weight than rubber, easing installation in tight or complex spaces, such as HVAC or automotive systems.

Cost Considerations

Cost is a pivotal factor in material selection. Silicone hoses, while the priciest, offer longevity and performance that can offset their initial expense in demanding applications. PVC hoses are the most economical, fitting for low-temperature, cost-sensitive uses where frequent replacement is viable. Rubber hoses strike a middle ground, balancing durability and affordability, though they may need replacing more often in tough conditions.

Conclusion

Choosing between silicone, PVC, and rubber duct hoses depends on the application's specific requirements. Silicone excels in high-temperature, durable scenarios; PVC suits chemical-resistant, budget-friendly needs; and rubber offers strength for abrasive settings. By weighing performance, durability, and cost, the best material can be selected to meet the task at hand effectively.

Ecoosi specializes in industrial ducting hose solutions. If you have questions or need additional information about our flexible duct hoses, please do not hesitate to click contact us or send an email to:info@eiduct.com or Whatsapp to:+86-187-1155-3123, or our other website:ductinghose.com, we will try our best to support you!

German

German French

French Spanish

Spanish Portuguese

Portuguese Russian

Russian Japan

Japan Italian

Italian

Send Email

Send Email Jim5040

Jim5040