Something You Must Know About Dust Explosion Protection

Dust explosion refers to a dust cloud formed by combustible dust mixed with air in a confined space. Under the action of an ignition source, the formed dust-air mixture burns rapidly and causes a chemical reaction in which the temperature and pressure rise sharply.

In recent years, dust explosions are mostly accompanied by aluminum powder, magnesium powder, aluminum processing grinding powder, various plastic powders, intermediates of organic synthetic drugs, wheat flour, sugar, wood chips, dyes, bakelite ash, milk powder, tea powder, tobacco Production and processing places where powder, coal dust, plant fiber dust, etc. are generated.

The generation of dust explosion usually requires the following five factors:

01 - The dust itself is flammable or explosive;

02 - The dust must be suspended in the air and mixed with air or oxygen to reach the explosion limit;

03 - There is enough thermal energy to cause dust explosion, i.e. ignition source;

04 - Dust has a certain diffusibility;

05 - Enclosed spaces (containers, rooms, buildings, pipes).

The explosion of dust is formed by the following three steps:

01 - The suspended dust is rapidly retorted or gasified under the action of a heat source to produce combustible gas;

02 - Combustible gas mixes with air and burns;

03 - The heat released by the combustion of dust is transmitted to the nearby suspended or blown dust in the form of heat conduction and flame radiation. After this dust is heated and vaporized, the combustion cycle proceeds. With the successive progress of each cycle, its reaction speed gradually accelerated, and finally formed an explosion through violent combustion. This explosion reaction, as well as the speed of the explosion flame, the speed of the explosion wave, and the explosion pressure, will continue to accelerate and increase, and develop in a jumping manner.

What are the commonly used protective measures or solutions to deal with dust explosions?

There are five main types: anti-static, anti-explosion, explosion-venting, explosion-suppression, and explosion-proof. The main protective equipment involved in the above five scenarios includes:

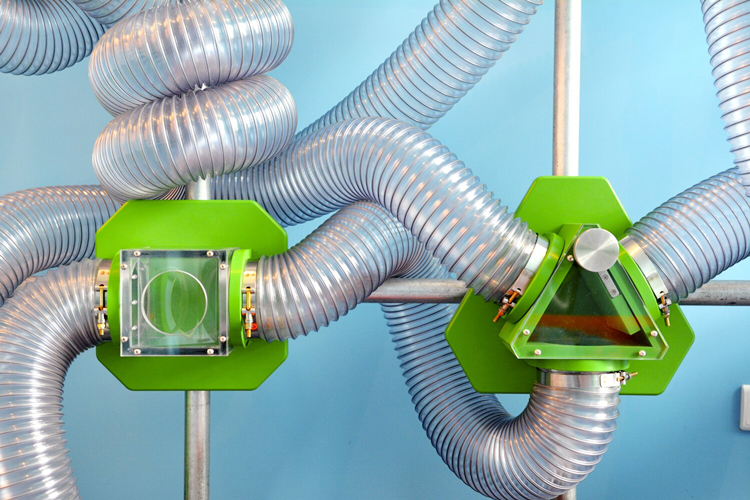

Antistatic Dust Collection Hose

Explosion Panel

Explosion Vent

Flameless Venting

Explosion Isolation Valve

Explosion Suppression Systems

In practical applications, not every protective measure is used alone, and multiple protective measures are often used in combination to achieve more reliable and economical protection purposes.

If you have any interest in our anti-static dust collection hose, please feel free to click contact us or send an email to: info@eiduct.com or mobile (WhatsApp): 00 -86-187-1155-3123, or our other website: Ductinghose.com, we're here for you!

German

German French

French Spanish

Spanish Portuguese

Portuguese Russian

Russian Japan

Japan Italian

Italian

Send Email

Send Email Jim5040

Jim5040