Silicone Duct Hose for Film Blowing Machines: Technical Applications and Engineering Advantages

In film blowing and plastic extrusion operations, airflow stability, thermal resistance, and system reliability directly impact product quality and production efficiency. Silicone duct hose is widely specified in film blowing machines due to its ability to operate continuously in high-temperature environments while maintaining flexibility and clean airflow.

For OEMs, equipment engineers, and plant managers, selecting the correct ducting material is critical to long-term machine performance.

Role of Airflow in Film Blowing Machines

A film blowing machine relies on controlled airflow to:

Cool the extruded film bubble

Maintain uniform film thickness

Stabilize bubble diameter

Regulate temperature near the die head

Air is supplied and circulated through air rings, blowers, heaters, and exhaust systems. Any airflow restriction, leakage, or heat-related failure can result in film defects or unplanned downtime.

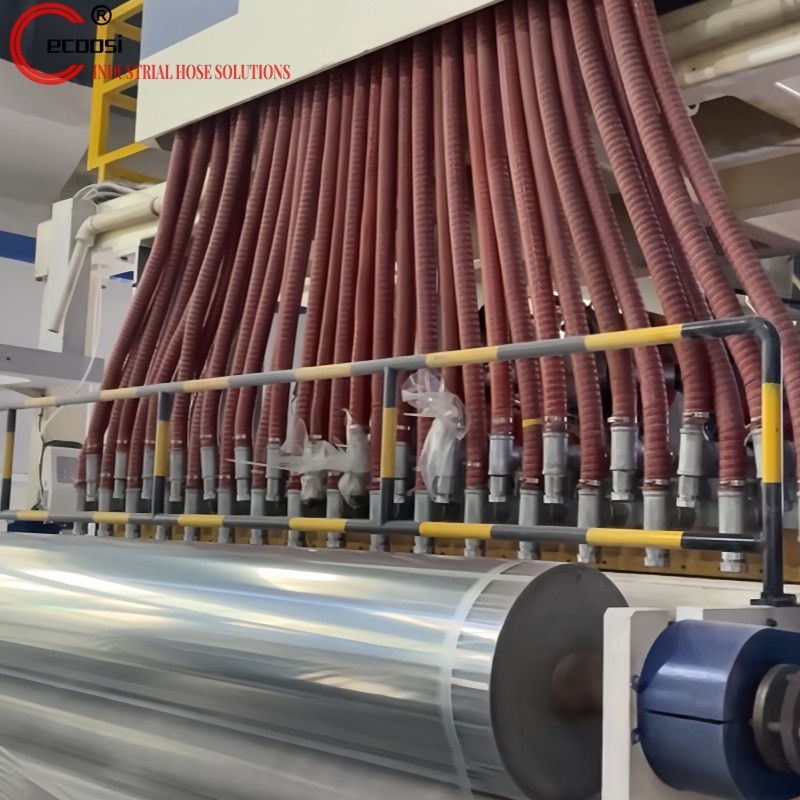

Engineering Applications of Silicone Duct Hose

Air Ring Cooling Connections

Silicone duct hose is used to connect blowers to air rings, delivering consistent cooling air around the film bubble. The hose’s flexibility allows precise routing while maintaining airflow efficiency, which is essential for thickness control and process stability.

High-Temperature Air Transfer Near Extrusion Zones

Near the extruder and die head, ambient temperatures are significantly elevated. Silicone duct hose maintains structural integrity and flexibility under continuous heat exposure, unlike PVC or standard rubber hoses that may harden or crack over time.

Ventilation and Thermal Management

Silicone duct hose is commonly used in hot air exhaust and ventilation systems to remove excess heat from the machine enclosure. Effective heat removal helps protect electrical components and ensures stable operating conditions.

Blower, Fan, and Heater Interfaces

Blowers and heaters generate vibration and thermal expansion. Silicone duct hose accommodates movement, absorbs vibration, and maintains airtight connections, reducing mechanical stress on rigid components.

Key Technical Advantages for Industrial Buyers

Continuous High-Temperature Performance

Silicone duct hose is typically rated for continuous operation up to 260°C (452°F) or higher, depending on reinforcement and wall construction. This makes it suitable for long production cycles in extrusion and film blowing lines.

Flexibility and Installation Efficiency

The hose’s high flexibility allows installation in confined machine layouts without compromising airflow. This reduces installation time and simplifies retrofitting or equipment upgrades.

Clean, Non-Contaminating Material

Silicone is odorless, non-toxic, and free from plasticizers. This is critical for film blowing applications involving food-grade or medical packaging, where air purity is a requirement.

Durability and Reduced Maintenance

Silicone duct hose resists heat aging, ozone, and environmental degradation, resulting in longer service life and reduced maintenance intervals compared to conventional ducting materials.

Low Airflow Resistance

A smooth internal bore minimizes pressure loss, improving blower efficiency and reducing energy consumption.

Typical Specifications Considered by Engineers

When specifying silicone duct hose for film blowing machines, engineers typically evaluate:

Temperature rating (continuous and peak)

Hose diameter and length tolerances

Reinforcement type (fabric, wire, or spring steel)

Minimum bend radius

Pressure and vacuum ratings

Compatibility with clamps and connectors

Selecting the correct specification ensures reliable airflow and long-term performance.

Common Installation Points in Film Blowing Lines

Silicone duct hose is most commonly installed in:

Air ring cooling systems

Hot air and cold air circulation ducts

Blower-to-manifold connections

Heater and temperature control systems

Exhaust and ventilation lines

Standardizing silicone duct hose across these applications simplifies maintenance and spare parts management.

Value for OEMs and Plant Operators

From a B2B perspective, silicone duct hose delivers measurable operational benefits:

Improved film consistency and reduced scrap

Increased equipment uptime

Lower total cost of ownership

Compliance with hygiene and safety standards

Reliable performance in continuous production environments

Conclusion

For film blowing machines and plastic extrusion equipment, silicone duct hose provides a technically sound solution for airflow management in high-temperature environments. Its combination of thermal stability, flexibility, and durability makes it a preferred choice for engineers, OEMs, and industrial buyers seeking reliable, long-term performance.

By specifying industrial-grade silicone duct hose, manufacturers can optimize machine efficiency, protect critical components, and maintain consistent film quality throughout the production cycle.

Ecoosi specializes in manufacturing all kinds of silicone duct hoses. If you have questions or need additional information about our industrial duct hoses, please do not hesitate to click contact us or send an email to:info@eiduct.com or Whatsapp to:+86-187-1155-3123, or our other website:ductinghose.com, we will try our best to support you!

German

German French

French Spanish

Spanish Portuguese

Portuguese Russian

Russian Japan

Japan Italian

Italian

Send Email

Send Email Jim5040

Jim5040