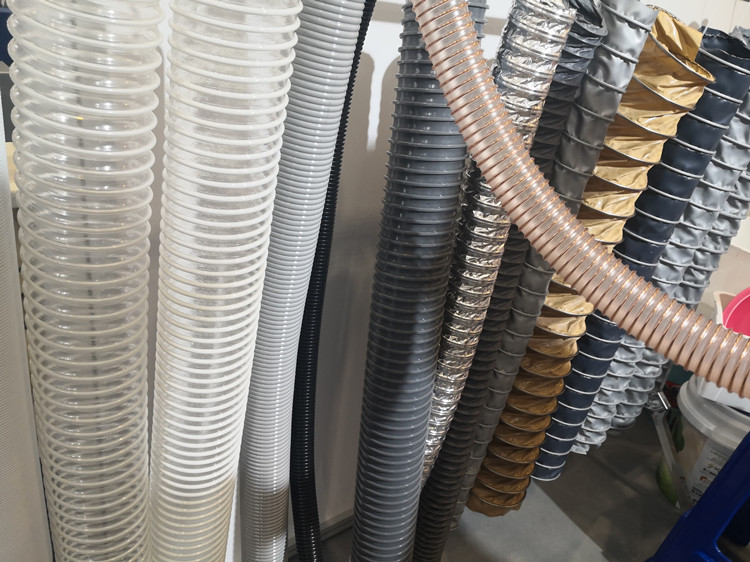

What Is the Best Flexible Hose for Industrial Use?

Flexible hoses are a critical component in many industrial applications, used for transferring air, liquids, gases, or materials. Choosing the best flexible hose for your specific needs ensures efficiency, safety, and durability. Here’s an in-depth look at the factors to consider and some of the top hose options for industrial applications.

Factors to Consider When Choosing an Industrial Flexible Hose

Material Compatibility

The hose material must resist the chemical properties of the substance it transports. For example:

1. Polyurethane hoses: Ideal for abrasive materials such as powders or granules.

2. PVC hoses: Suitable for general air or light-duty chemical transfers.

3. Silicone hoses: Great for high-temperature applications.

Temperature Range

Industrial environments often involve extreme temperatures. High-temp silicone or metal-reinforced hoses work well in such conditions, while flexible PVC hoses handle lower temperature ranges.

Flexibility and Bend Radius

Tight spaces or applications requiring frequent bending call for hoses with excellent flexibility.

Durability and Abrasion Resistance

Abrasive materials or rough handling require hoses with thick walls or reinforcement, such as polyurethane or metal-reinforced options.

Pressure Requirements

Applications involving high-pressure air or liquids need hoses with reinforced linings to prevent bursting.

Compliance Standards

Ensure the hose meets industry standards such as FDA compliance for food-grade hoses or fire resistance for exhaust systems.

Top Flexible Hoses for Industrial Applications

Polyurethane Duct Hoses

1. Best for: Abrasive materials, dust collection, and material handling.

2. Key features: Lightweight, excellent abrasion resistance, and flexibility.

3. Example: Urethane duct hoses are common in woodworking or grain transfer applications.

PVC Flexible Hoses

1. Best for: Ventilation, light chemical handling, and general-purpose applications.

2. Key features: Cost-effective, lightweight, and corrosion-resistant.

3. Example: PVC suction hoses are popular for water transfer and low-pressure fluid movement.

Silicone Hoses

1. Best for: High-temperature environments.

2. Key features: Heat resistance up to 500°F, non-toxic, and food-safe options available.

3. Example: Used in plastic processing or pharmaceutical industries.

Metal-Reinforced Flexible Hoses

1. Best for: Extreme conditions involving high pressure, temperature, or corrosive materials.

2. Key features: Exceptional strength, heat resistance, and durability.

3. Example: Stainless steel hoses in petrochemical or high-pressure steam systems.

EPDM Rubber Hoses

1. Best for: Chemical resistance and outdoor applications.

2. Key features: UV-resistant, weather-resistant, and highly flexible.

3. Example: Ideal for water and air transfer systems.

How to Maintain Your Flexible Hose

1. Regular Inspection: Check for cracks, leaks, or signs of wear.

2. Proper Storage: Avoid kinks or crushing by coiling hoses neatly.

3. Clean After Use: Prevent residue buildup, especially when handling abrasive or corrosive materials.

4. Replace When Necessary: Don’t compromise safety by using a damaged hose.

Conclusion

The best flexible hose for industrial use depends on your specific application. Factors like the transferred material, temperature, and pressure requirements all influence the choice. Polyurethane and silicone hoses are excellent for specialty applications, while PVC and EPDM rubber hoses are versatile and cost-effective solutions.

Ecoosi Industrial Co., Ltd. specializes in producing flexible hose products. If you have questions or need additional information about our flexible hoses, please do not hesitate to click contact us or send an email to:info@eiduct.com or Whatsapp to:+86-187-1155-3123, or our other website:ductinghose.com, we will try our best to support you!

German

German French

French Spanish

Spanish Portuguese

Portuguese Russian

Russian Japan

Japan Italian

Italian

Send Email

Send Email Jim5040

Jim5040