What is Brake Ducting? An In-Depth Look at How It Works and Why It’s Essential

In the world of automotive performance, brake ducting is a crucial component that often flies under the radar. It plays a pivotal role in helping vehicles maintain optimal braking performance, especially in high-speed or high-demand situations. Whether on the racetrack, winding mountain roads, or during intense city driving, brake ducting is integral to safe and effective braking. Here’s a look at what brake ducting is, how it works, and why it’s so important.

Understanding Brake Ducting: The Basics

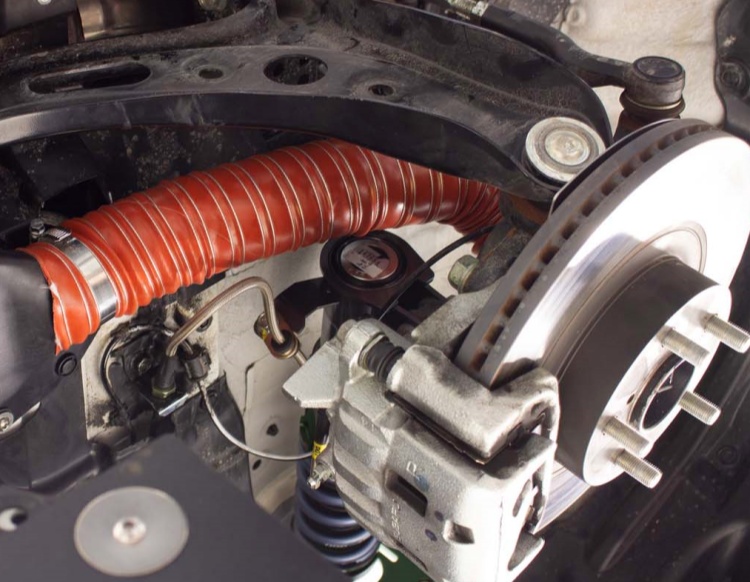

Brake ducting refers to a system of ducts or hoses designed to channel cool air toward the vehicle's brakes, typically focusing on the rotors and calipers. By delivering a steady stream of air to the brakes, the ducting helps manage heat buildup. Without proper cooling, the brakes can reach temperatures that compromise their ability to function, potentially leading to brake fade, warping, or even brake failure.

Most modern high-performance vehicles come equipped with some form of brake ducting, but it’s also commonly added as an aftermarket upgrade for drivers who want to boost their vehicle's braking reliability and performance.

Why Brake Cooling Matters

Brakes work by creating friction between the brake pads and rotors, slowing the vehicle down through resistance. This friction generates a considerable amount of heat, especially during intense braking situations. If this heat is not managed, it can reduce braking performance in several ways:

Brake Fade: Excessive heat can cause the brake pads to lose their friction, leading to a phenomenon known as brake fade. When brake fade occurs, the stopping power decreases, making it harder to slow down or stop the vehicle.

Warping and Damage: High temperatures can also cause rotors to warp, which leads to an uneven braking surface. Warped rotors create vibrations and reduce the effectiveness of the braking system.

Premature Wear: Constant exposure to high temperatures can accelerate the wear of brake pads and rotors, resulting in more frequent replacements and increased maintenance costs.

How Brake Ducting Works

The basic principle behind brake ducting is simple: it uses a system of ducts and hoses to channel cool air from outside the vehicle directly onto the brakes. Most brake ducting setups begin with an inlet near the front of the car (often in the bumper or lower grille) that captures cool air. This air is then directed through ducts or hoses to the wheel wells, where it flows over the brake components, primarily the rotors and calipers.

By keeping these components cool, brake ducting helps maintain optimal braking performance under demanding conditions. This cooling is especially important in motorsports, where consistent, reliable braking can make the difference between winning and losing a race.

Types of Brake Ducting Systems

Brake ducting systems vary widely based on the vehicle’s design, the intended application, and the specific cooling needs. Here are the main types of brake ducting systems:

OEM Brake Ducting: Many high-performance cars come equipped with factory-installed brake ducting. These systems are generally well-integrated into the vehicle's design but may be limited in their cooling capacity.

Aftermarket Brake Ducting Kits: For drivers who need enhanced cooling, aftermarket brake ducting kits are widely available. These kits are typically more robust and efficient than factory systems and are especially popular in racing and high-performance vehicles.

Custom Brake Ducting: In racing applications, custom brake ducting setups are common. Custom systems allow for tailored airflow, maximizing cooling for specific tracks or driving conditions.

Benefits of Brake Ducting

Brake ducting offers several key benefits, particularly for performance-oriented drivers:

Improved Braking Consistency: By managing heat more effectively, brake ducting ensures that the brakes perform consistently, even under high loads.

Extended Component Lifespan: By preventing excessive heat buildup, brake ducting reduces the wear on brake components, leading to longer intervals between replacements.

Enhanced Safety: Effective cooling reduces the risk of brake fade and failure, making driving safer, especially in demanding conditions.

When Is Brake Ducting Necessary?

While brake ducting is not essential for everyday driving, it’s highly recommended for:

Performance and Racing: Cars used in racing or high-speed driving benefit greatly from brake ducting.

Mountain Driving: Brakes are often used more intensively on steep grades, which can lead to overheating.

Towing and Heavy Loads: Vehicles towing heavy loads put extra strain on their brakes, which can benefit from added cooling.

Conclusion

Brake ducting may be an overlooked component for most drivers, but it’s a crucial addition for those seeking to maximize brake performance and safety in demanding situations. By managing brake temperatures, ducting ensures consistent performance, prolongs component life, and enhances overall safety. For drivers who push their vehicles to the limit, brake ducting is more than an upgrade—it’s an essential tool to keep their brakes, and themselves, safe on the road.

Ecoosi’s high-quality brake ducting hose is produced by double-layer silicone-coated fiberglass reinforced with a spring steel wire helix & external filament fiberglass cord. If you have questions or need additional information about this product, please do not hesitate to click contact us or send an email to:info@eiduct.com or Whatsapp to:+86-187-1155-3123,or our other website:ductinghose.com, we will try our best to support you!

German

German French

French Spanish

Spanish Portuguese

Portuguese Russian

Russian Japan

Japan Italian

Italian

Send Email

Send Email Jim5040

Jim5040